hello there

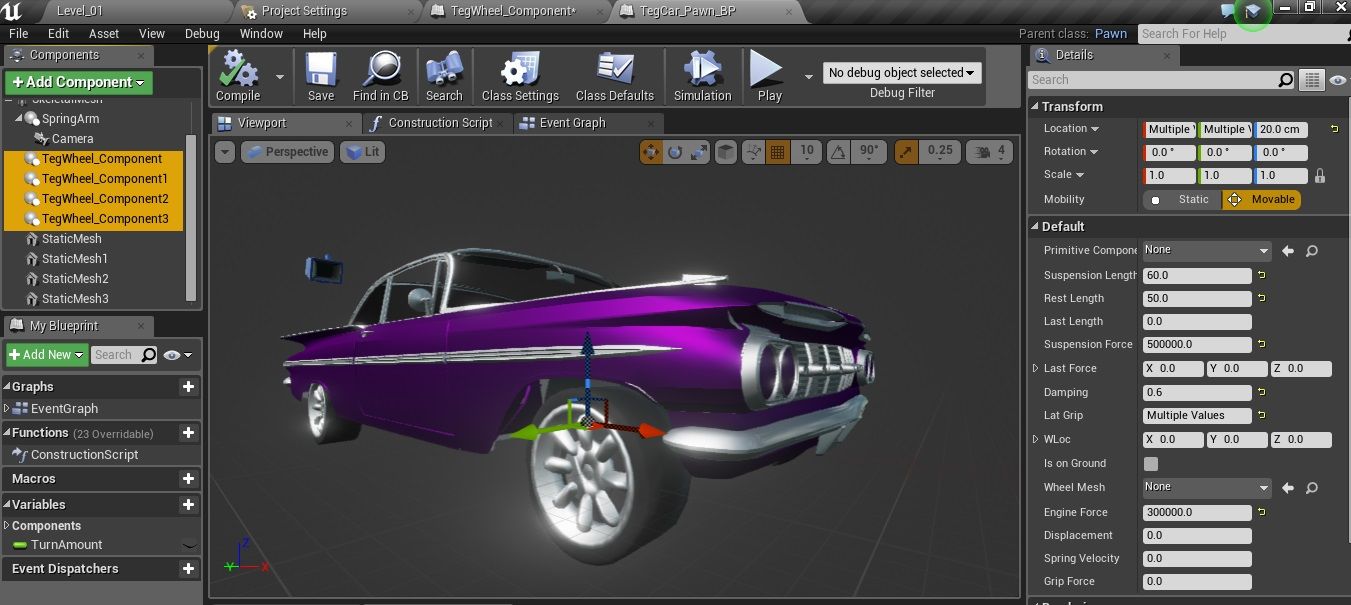

Here is a car example with custom physics in the form of a plugin. It is the end result of discussions in this thread. The download link is a full project with an example car on a test level.

(there is no blueprint version)

edit:

LATEST VERSION HERE:

Updated to 4.22.3 / VS2017

Download link https://www.dropbox.com/s/lybjonssfg…04.22.zip?dl=0

right click the .uproject file and select generate project files, then open the generated .sln on visual studio and build it

what you will get is an updated version of this

1.either make or download your own car model

2. the car body needs to be a skeletal mesh with 1 single bone which will be the center of gravity.

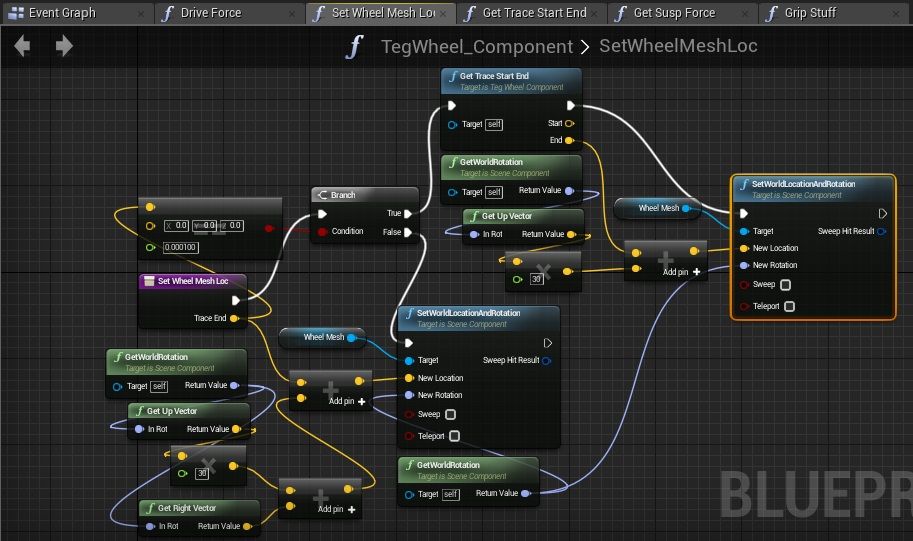

3. the wheels are a single static mesh

4. either duplicate or modify TegCar 8 blueprint with your own car model

5. adjust spring, engine etc settings to suit

6. make an ace game

old edits below:

4.20.3 Version HERE

@vr_marco kindly updated and shared this plugin to compile under UE 4.20.3 / VS2017

Download link: CarPluginProject.zip - Google Drive

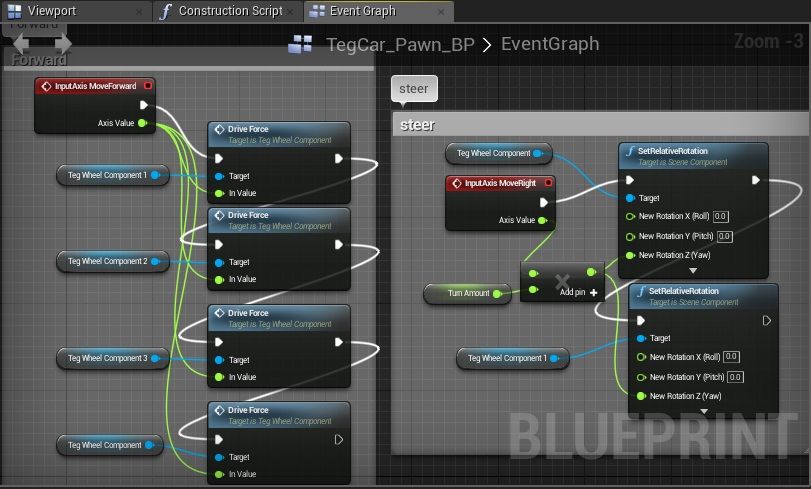

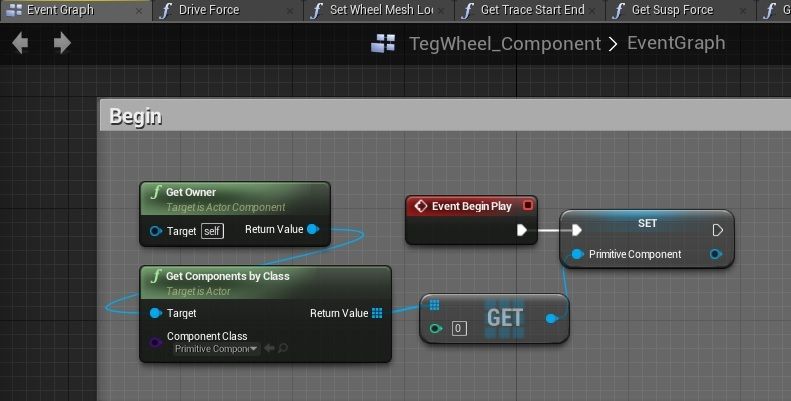

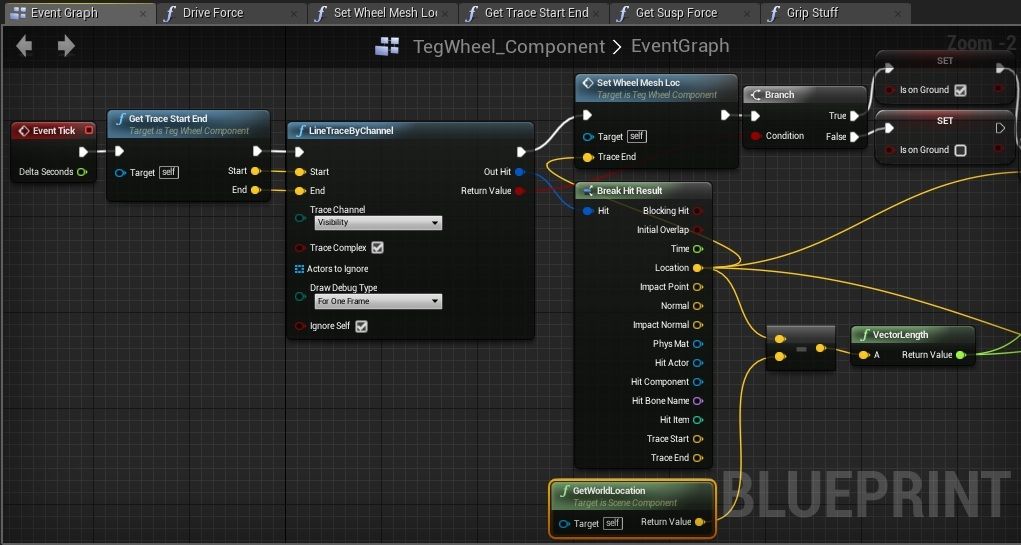

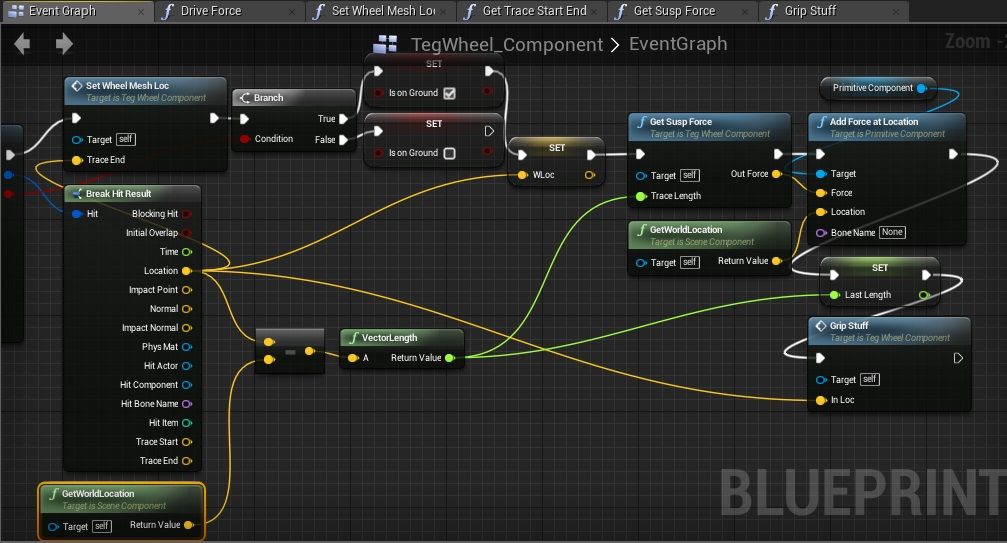

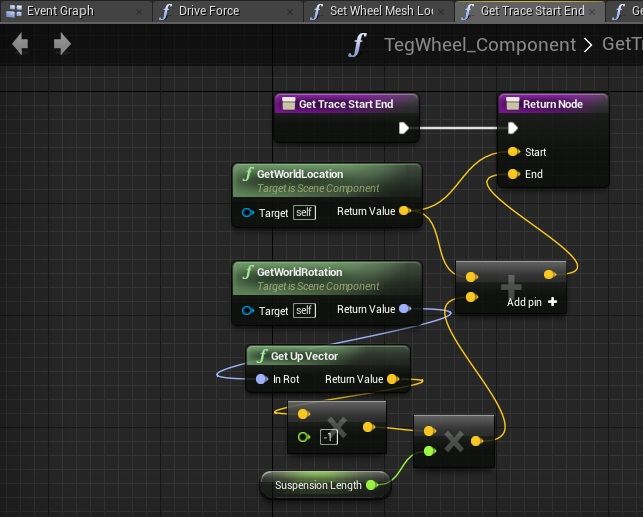

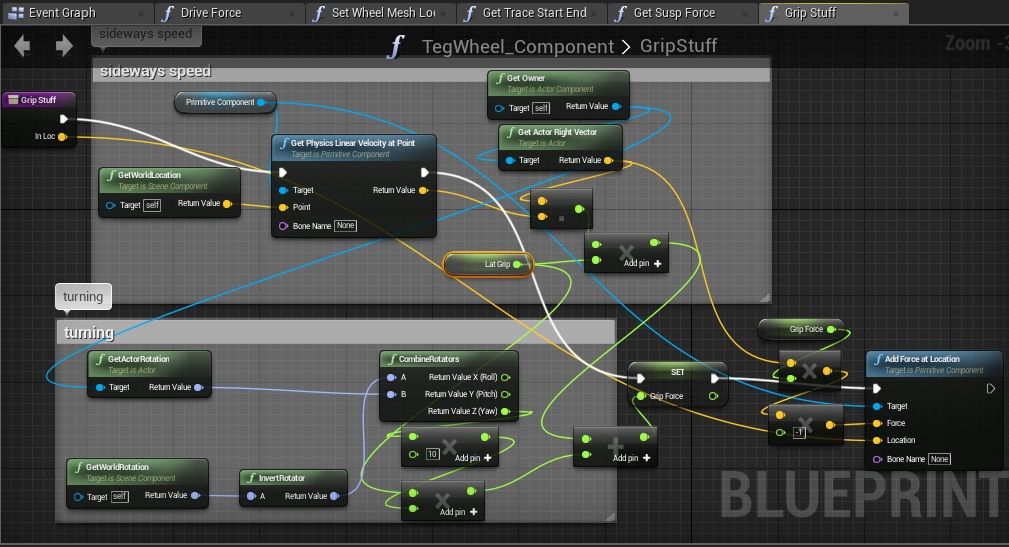

alright here is the last version of this i will give out. its a custom pawn class with custom 4 wheeled vehicle physics.

its the full project with an example car. the code is all nicely packed into a plugin so you can add it to your own project.

please feel free to use or modify it in any way you see fit. if you find a way to improve it please let everybody know on here.

big credits to and BoredEngineer without whom it would not have been possible ![]()

CarPlugin v0.4

for UE 4.10 and VS2015

right click the .uproject file and select generate project files, then open the generated .sln on visual studio and build it

have fun

old vid here (v0.1) UE4 Car Physics Plugin - YouTube

old versions:

https://forums.unrealengine.com/showthread.php?48843-Horrible-Car-Physics

in that thread, 0lento was kind enough to provide some pointers and useful links.

https://forums.unrealengine.com/show…l=1#post396144

https://forums.unrealengine.com/show…l=1#post396237

https://forums.unrealengine.com/show…l=1#post396367

https://forums.unrealengine.com/show…l=1#post396409

im currently in the process of doing some experiments with blueprints very loosely based on the hover component tutorial.

nothing decent enough to show yet sorry.

if anyone has anything to add or ask please feel free ![]()

thanks